Dies & Moulds Jigs Fixtures

Dies & Moulds

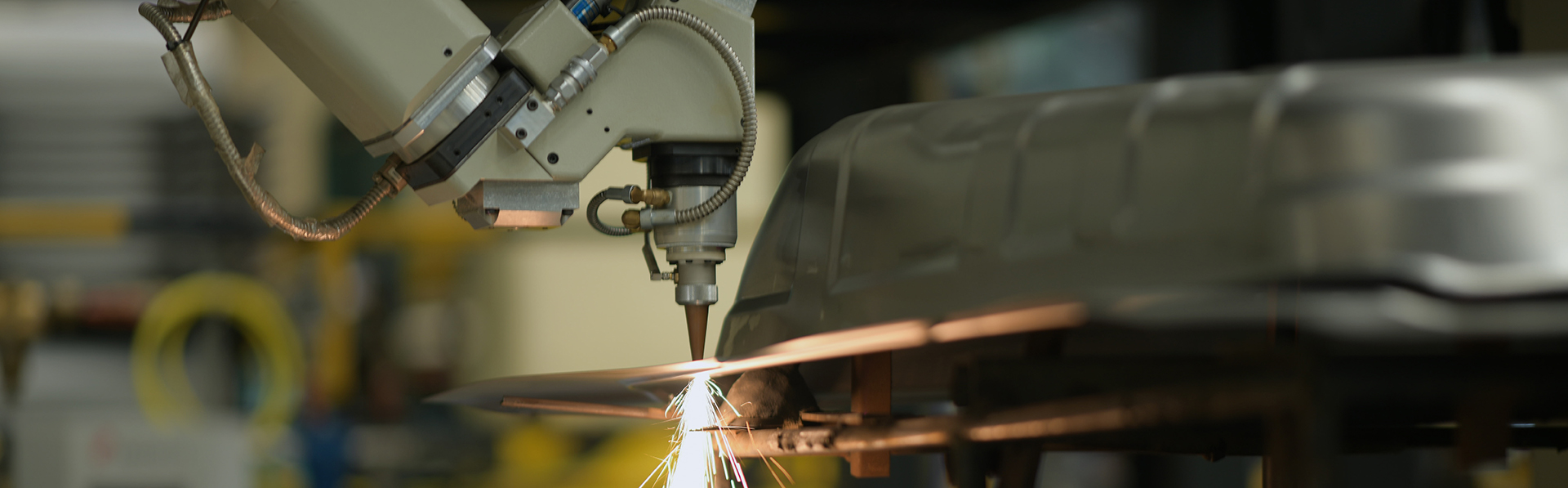

Metal Stamping Dies Overview

Thai Rung Tools and Dies Co. Ltd. (‘TRT’) is TRU’s Bangkok-based dedicated subsidiary for the manufacture of dies and jigs. TRT can produce 100 sets of various precision dies per year, up to a maximum size of 2.5 x 5.0 meters.

Dies for automotive parts are mostly made to order for automakers such as Isuzu, Auto Alliance Thailand (Ford/Mazda), GM, Toyota, Honda, and Nissan, for both the domestic and overseas markets. We also produce dies for makers of electrical household appliances, air-conditioning equipment, etc. The range of dies includes progressive dies, cutting dies, and bending dies.

Throughout TRT’s thirty years of growth and development, we have acquired advanced die production technology and management techniques, as well as building on practical experience, and have developed and perfected quality control procedures to meet customers’ world-class product quality requirements. At the same time, we pay constant close attention to controlling operating costs and increasing efficiency, so as to ensure competitive pricing and high-quality services for our customers.

Quality and customer satisfaction are the company’s watchwords.

Jigs and Checking Fixtures

Thai Rung Tools and Dies Co. Ltd. (‘TRT’) is TRU’s Bangkok-based dedicated subsidiary for the manufacture of dies and jigs and checking fixtures for the OEM Market.

Throughout TRT’s thirty years of growth and development, we have acquired advanced jig and fixture production technology and management techniques, as well as building on practical experience, and have developed and perfected quality control procedures to meet customers’ world-class product quality requirements. We have advanced in-house capability in the design and manufacture of jigs and fixtures. Our CNC wire cutting machines, digitizer and CAD/CAM facilities – Catia, Surfcam, Cliks, PDD and Unigraphics NX4 – are all fully utilized in order to ensure data accuracy, product precision and timely delivery.

Products

- Main assembly jigs for complete vehicles

- Sub-assembly jigs and checking fixtures for door, roof, chassis, hood , wheelhouse, etc.

- Manual, pneumatic semi-automatic, fully automatic