Experimental Testing

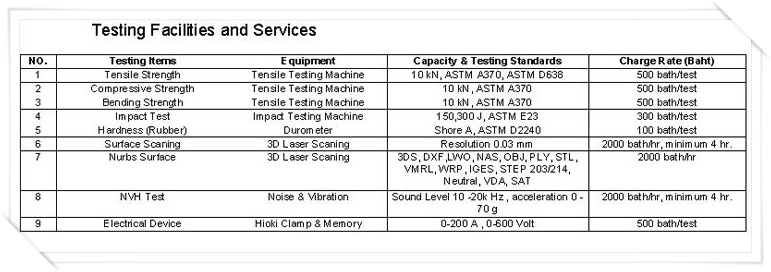

The last step in the engineering design process is the try-out and testing program, which provides assurance of product quality. It can be carried out either in the laboratory or through simulation, and also by using CAE (computer aided engineering) in parallel with the engineering design. We have a full complement of tools and equipment for carrying out tests of various kinds, such as tensile, impact, NVH (noise, vibration and harshness), rubber hardness, electrical and thermal cycles, as well as basic product tests such as those for noise and sound, squeak and rattle in passenger compartment, vehicle dynamics, electrical shock, electromagnetic compatibility, durability and ride comfort. In the future we plan to make use of a virtual reality studio to gather information and feedback on customer requirements. Customers will be able to correct design work, paint, surface, etc. at each stage before mock up, clay model and prototype are produced.

Thermal Cycles Test

Thermal Cycles Test

Julabo refrigerated and heating circulators are suitable for temperature application to external systems with simultaneous operation in the bath tank, with a working temperature range of -30?C to +200?C. This equipment can also be used for corrosion testing, by adding about 5% of sodium chloride by weight in accordance with standard test type D1193, which requires that the sodium chloride be substantially free of nickel and copper and containing on the dry basis not more than 0.1% sodium iodide and not more than 0.3% total impurities by weight. Some salts contain additives that may act as corrosion inhibitors, so careful attention is paid to the chemical content of the salt. In any case, test methods can be modified to meet customer requirements.

Electrical Test

The Hioki 3284 clamp-on AC/DC HiTester is easy to use, with no need to tap into or connect to lines. The tester supports a range of functions including an automatic zero adjusts function that changes a troublesome task into a one-touch operation. The 3284 is capable of measuring various functions and displaying true RMS values, allowing measurement of peak hold values for either voltage or current. Using the 3284’s external output function in combination with a Hioki 8808 memory recorder enables recording of current and frequency fluctuations.

Universal Tensile Test

The Instron 3366 universal testing machine can be used for both tension and compression applications for tests up to 10 kN (2,250 lbf). Instron electromechanical load frames are designed to apply a load to a test specimen via the moving crosshead. The drive system moves the crosshead up to apply a tensile load, or down to apply a compressive load on the specimen. In addition, the test types may include tensile, compression, shear, flexure, peel, tear, cyclic and bend tests.

Tensile testing involves pulling on a specimen material to determine the relationship between force and stretch, and the force at failure. This method can be used for practically any kind of material, and many material properties can be determined by tensile testing. As the material is pulled, its strength is revealed, along with how much it will elongate. Data from testing are used to determine elastic limit, elongation, modulus of elasticity, proportional limit, reduction in area, yield strength, yield point and other tensile properties. Tensile tests at elevated temperatures provide creep data. Procedures for tensile tests of metals are given in ASTM E-8, while those for plastics are contained in ASTM D-638, ASTM D-2289 (high strain rates), and ASTM D-882 (thin sheets). ASTM D-2343, D-897 and D-412 outline methods for tensile testing of glass fiber, adhesives and vulcanized rubber respectively.

Impact Test

Impact testing machines are designed to measure the toughness of metal materials under dynamic loading in bending and tension. The impact test principle is that latent energy before and after impact can be displayed on the graduation dial on the testing machine, and the difference between them can be calculated to give the absorption performed by the test specimen. The quantity usually measured is the energy absorbed in breaking the specimen in a single blow, as in the Charpy or Izod impact tests, and tension impact test. Impact tests are also performed by subjecting specimens to multiple blows of increasing intensity, as in the drop ball impact test, and repeated blow impact test.

Vibration and Acoustic Test

This testing method is applied to noise, vibration and harshness (NVH) of vehicle components and accessories. It can help investigate the root cause of problems by using contour and waterfall displays to differentiate driving forces from natural resonances on variable speed objects. It can also quantify the performance of parts by overlaying measurements, and trigger on transient events like squeaks and rattles. Acoustic testing measures sound using true digital 1/1- and 1/3-octave filters to meet ISO and ANSI standards, and measures sound pressure levels using linear and A-weighting scales.

Starting with market research, through initial definition of specifications, and on through the stages of sketching, rendering Our Research and Development Department uses programs such as PhotoShop, Illustrator, CorelDraw and Alias Studio Tools to create two and three dimensional surface modeling, and Imagineering for the concept design stage, while for reverse engineering they make use of Scan 3 –3-D surface modeler prior to building the CAD (computer aided design) model.

The fact that we are so well equipped in the field of design enables us to easily to carry out product review while the design process is ongoing, and customers can alter product characteristics according to requirements, so as to respond quickly to changes in market demands